Aviation Component Maintenance, Repair and Overhaul Services

We have more than 30 years of experiences in aircraft and engine component repair and overhaul, and have been a trusted and reliable repair shop in this part of the globe. Under our Civil Aviation Authority of New Zealand (CAANZ) Part 145 Maintenance Organization Certificate, we provide MRO and engineering services of the highest quality to a wide range of aviation Component by various OEMs. We provide specialist component repairs particularly for the Rolls Royce M250 engines, which includes applying an extensive range of coatings for abradable sealing, wear resistance, dimensional restoration and thermal barrier coatings.

Industrial Services

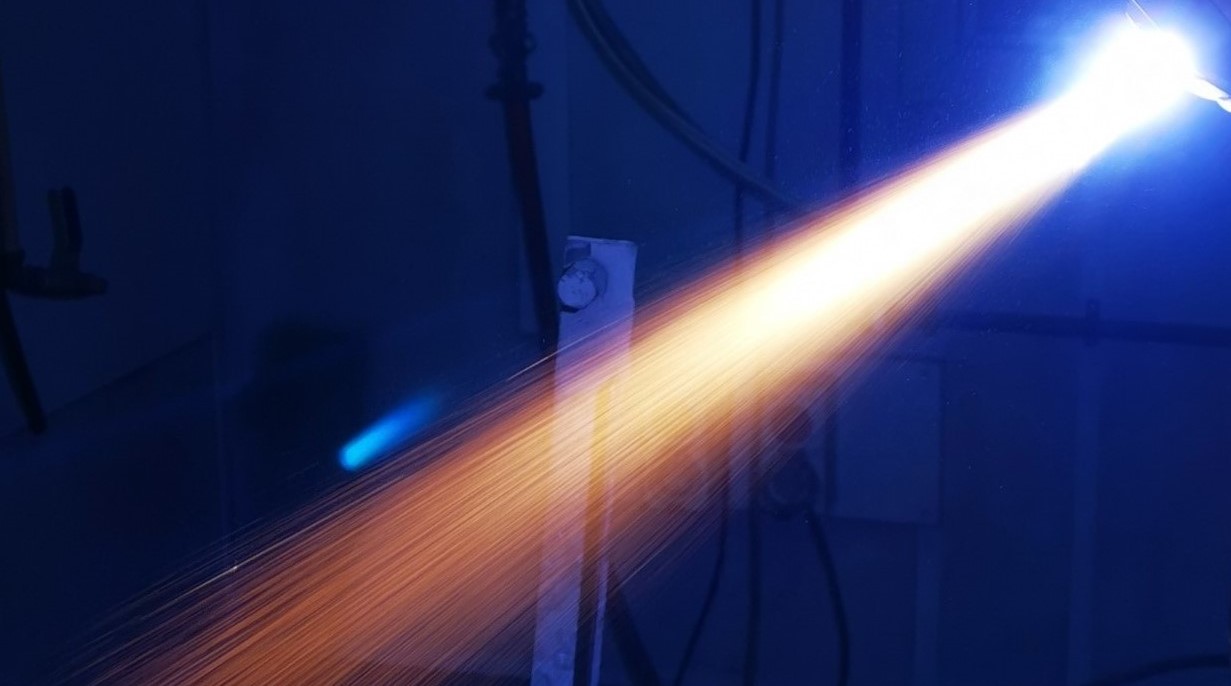

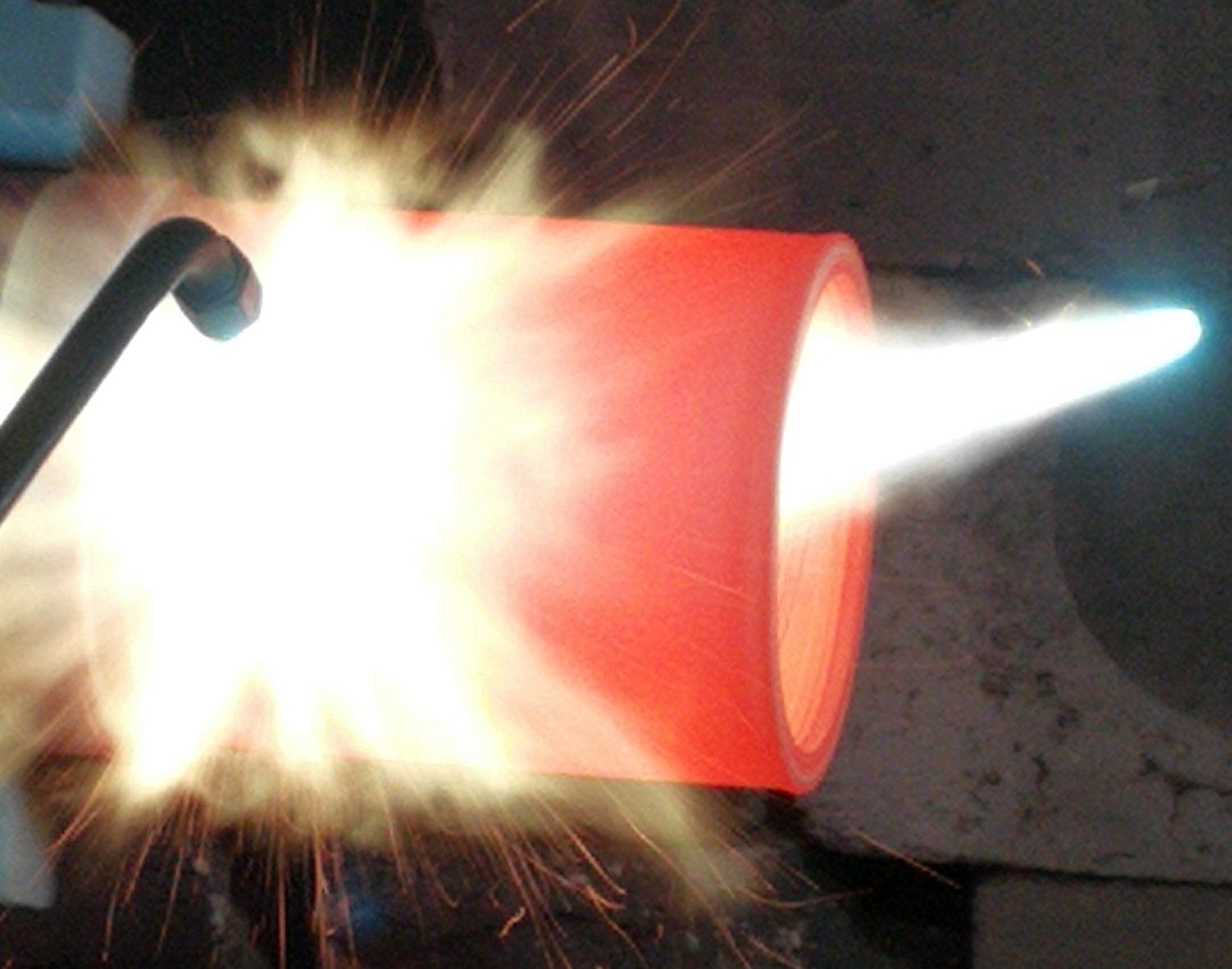

Hardface Solutions is the industrial division of Aerospace Thermal Coatings Ltd specializing in component repair, material enhancements and hard facing for extreme wear resistance applications. With a diverse range of surface engineering technologies in our facility, we deliver solutions to complex problems faced by various industries such as extreme wear and thermal degradation, from the development to the implementation phase. Our vast experiences range from applying soft aluminium bronze coatings for bearing sliding wear to applying extreme wear resistant hard face tungsten carbide overlay. Robotized control of the Plasma Transfer Arc (PTA) overlaying process ensures that extremely wear resistant overlays can be uniformly achieved across the various thickness. Depending on the wear application, with a wide variety of hardfacing options at our disposal, you can be rest assured that the applied overlay protects components from excessive wear, impact, abrasion and corrosion thereby reducing unnecessary downtime and maintenance costs.

Engineering Services

ATC specialize in fixture design and fabrication for a wide range of applications such as protective hard masks, testing rigs, spring tester, pressure testing. Our development team works with customers closely for prototyping work and carry out in-house testings. Our Brown & Sharpe Coordinate Measuring Machine (CMM) is programmable to accurately measure complex geometries and profile measurements. Contact us for relevant case studies and discuss how our services might help in your applications.

What We Offer...

Contact us to learn how surface engineering enhances the characteristics of your component, and extends the service life, thereby reducing downtime and maintenance costs.

Aviation MRO

In aircraft turbine component repairs, Aerospace Thermal Coatings Ltd is involved in repairs to several engine types.

Read MoreComponent Services

We offers a full range of thermal sprayed coatings to both OEM and repair/remanufacturing customers.

Read MoreEngineering Services

We operate a CNC controlled Brown & Sharpe Co-ordinate Measuring Machine, manufactured by Hexagon Metrology.

Read More